FlexFlow X™: Better Breakthroughs For Tissue Producers

March 15, 2021

The absence of innovative new fabrics for tissue machines might lead to the incorrect conclusion that everything that can be done has been done, and tissue producers are highly satisfied with the products already in the market.

AstenJohnson’s in-depth conversations with tissue producers paint a different picture. Tissue is a dynamic market with numerous opportunities for improvement. One is the tissue segment’s slow acceptance of seamed press fabrics. While 90% of the fabrics for other paper grades are seamed, only about 20% of tissue fabrics are seamed. And for good reason.

Given the light weight of tissue sheets, traditional press fabric seams were leaving lasting impressions on the sheets. Not just unsightly, these seam marks can lead to disruptions in downstream converting operations.

So, the mission at AJ became how to invent the best non-marking seam. It took one year of work to analyze and adjust the seams to create FlexFlow X™.

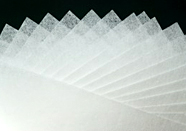

The key technical breakthrough came when the development team in Kanata, Ontario, developed an innovative Seam Flow Tester. The tester not only measured the mechanical aspects of a seam (profile, strength, integrity with the base fabric, etc.) but also added another aspect — flow patterns. With the ability to now correlate mechanical disruptions and flow pattern disruptions to seam performance, product designers began to tweak the FlexFlow X seam design and construction to minimize the disruptions and virtually eliminate tissue sheet marking.