In Our element™

October 19, 2020

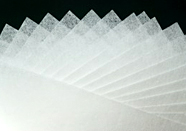

Competitive “triple-layer” press fabric structures have a woven single-layer cloth, or a nonwoven material, that is needled over the two-layer fabric. This requires that the needled layer be a fine mesh, minimizing the third layer’s contribution to void volume (greater void volume is necessary for better de-watering). Also, the stitched layer must be cut to form a flap — increasing the potential for seam defects.

The nonwoven third layer in the innovative element fabric is internal — not needled on or added on to the surface. Since it doesn’t contact the paper sheet, the nonwoven layer is extremely customizable in terms of weight, permeability, caliper, void volume, and compressibility. And since the seam is formed from the outer layers, there is no need to cut through the internal third layer. This contributes to seam integrity and less marking of the sheet during pressing.

All press fabrics take time to start up and settle in. They need to pass through the press section enough times for their batt structure and base construction to achieve optimum density. When element starts up, it settles in like a dream — thanks to the Nitro™ start-up aid. Embedding the Nitro aid in the fabric layers between the batt and the yarn temporarily increases the density of the fabric — avoiding the traditional low initial density, which negatively impacts nip saturation and pressing efficiency.

Once it has done its job (reducing break-in time to allow higher initial tonnage), Nitro gradually exits the fabric over one to three days, and the press fabric settles in for a long, productive life.